Eli-Flex FR909/N60 is a two-part polyurethane resin, formulated to effect quick and easy repairs to damaged conveyor belting and other rubber components.

The product range has enjoyed rapid growth worldwide in the last few years.

Eli-Flex attributes

- Quick setting

- Easy to use twinpack mixing & application system

- Excellent flexibility

- High tear & impact-resistance

- Good wear & abrasion-resistance

- Broad spectrum chemical protection

- Flame retardant

- Low irritation potential

- No special tools or skills required

- Environmentally friendly handling properties

- Two Year shelf life

- Air transport friendly

- 150gram, 300gram and 500gram twin packs

- Non – shrinking

Available in liquid and paste versions

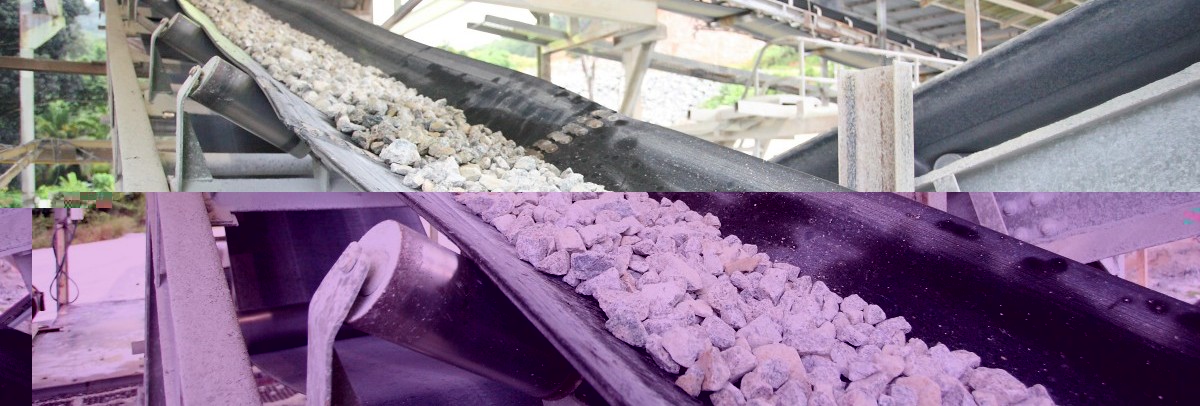

Conveyor Belt Applications

Eli-Flex can be used on all types of rubber and PVC belts. This includes fabric carcass, steel cable and steel cored belts. Eli-Flex is suitable for repairing holes, tears, splits, rips, gouges, missing filler strips, worn patches, clip joint / fastener sealing, edge repairs, re-building cleats, chevrons and sidewalls, worn drum lagging, rubber hose repair,roller coatings and friction linings, marine fender repair or rebuild.

Other uses include

Industrial tyre repair, vehicle anti-roll bar repair, general rubber rebuilding, rubber castings, rubber repair, mouldings, cable-entry sealing, marine fender repair, floating hose repair, watertight insulation, expansion joints, anti-vibration pads etc.

Eli-Flex FR909/N60 paste in action is a visual representation of this amazing product . Polymer Technologies Perth based in Landsdale Western Australia are the official suppliers of Eli-Flex in Australia and South East Asia.

We have a worldwide distribution network available, please contact us for any further information